PREMIUM WATERPROOF PRODUCT MANUFACTURERCNPW WATERPROOFPRODUCT MANUAL CREATIVE | NATURAL WONDERFULCNPW

CENTENNIAL WATERPROOFEXPERTS TAKE CAREOF CENTENNIAL BUILDINGS

Self-adhesive waterproof membrane seriesJH-C100 Polyester-Tire Self-Adhesive Polymer Modified Asphalt Waterproof MembraneJH-C200 PET Self-Adhesive Polymer Modified Asphalt Waterproof MembraneJH-C3000 High-Strength Cross Film Self-Adhesive Polymer Modified Asphalt Waterproof Membrane03 / 0405 / 0607 / 0809 / 1011 / 1213 / 14PRODUCT SERIESCOIL PRODUCT SERIESMoisture-laying waterproof membrane seriesJH-W100 Polyester-Tire Moisture-Laying Waterproof MembraneJH-W200 PET Polymer Reaction-Bonded Moisture-Laying Waterproof MembraneJH-W3000 High-Strength Cross Film PolymerReaction-Bonded Moisture-Laying Waterproof MembraneJH-N200 APP Plastic Modified Asphalt Waterproof MembranePolymer waterproof membrane seriesJH-P200 Non-Asphalt-Based Polymer Self-Adhesive Film Waterproof Membrane21 / 22

WATERPROOF PRODUCT SERIES PU waterproof membrane seriesJH-A100 Single-Component Polyurethane Waterproof CoatingJH-A200 Two-Component Polyurethane Waterproof Coating25 / 26Asphalt waterproof membrane seriesJH-G300 Non-cured Rubber Asphalt Waterproof CoatingPolymer emulsion waterproof membrane seriesJH-J300 Acrylic Ester Waterproof CoatingJH-J200 Cementitious Capillary Crystalline Waterproof Coating

COIL PRODUCT SERIES

03WATERPROOF PRODUCT MANUAL Polyester-Tire Self-Adhesive Polymer JH-C100 This product is a kind of flaky waterproof material that can be rolled, made of specially customized petroleum asphalt as the base material, supplemented by styrene-butadiene-styrene (SBS), styrene-butadiene rubber (SBR), tackifying resin as the modifiers, polyester fabric as the reinforced layer, with its upper surface covered covered with a peeling silicon coated isolation film.The product is safe, environmentally friendly and easy to apply.The polyester tire base fabric, as the reinforced layer, has good puncture and tear resistance.It has a lasting adhesion, and can form a full adhesive effect with the base.tion and cracking.It does not flow at high temperatures and does not crack at low temperatures, so it is suitable for Product characteristicsThe product is suitable for waterproofing non-exposed roofs and underground projects, as well as for waterproofing subways, tunnels, pools, canals, etc.Product applicationsBase surface cleaning and repair → applying base treatment agent → node pasting → positioning sealing and lap → protective layer applicationPlease noteApplication is strictly prohibited on rainy, snowy and windy days above grade 5.The temperature should not be lower than 5℃ during application.Product sizeInlayPolyester tire(PY)(mm)Adhesive surface(m)4.0Single-sided / double-sided10

04WATERPROOF PRODUCT MANUAL PackagDuring transportation and storage, products of different types and sizes should be stacked separately and should not be mixed.stored to avoid the sun and The product has a storage period of 1 year under normal transportation and storage conditions from the date of production.Executive standard of product performance: Requirements for the polyester tire (class PY) in GB 23441-2009 \"Self-adhering polymer modified bituminous waterproof sheet\"Product performanceMain itemsTensionN/50mm ≥Low temperature flexibilityN/mm ≥Persistent adhesivity min ≥3.0 mmType I4501.515Membrane and Membrane and No cracks at -30℃800Type IIImpermeable at 0.3Mpa for 120 minNote: See the standard content for other characteristics and requirements.

05Cold application: It is applied without the use of open flame, making it energy-saving, environmentally friendly, convenient, and economical.It has high elongation and outsanding shear resistance.Product characProduct sizeSurface materialPolyester film (PET)Thickness (mm)Adhesive surfaceModelLength(m)1.21.52.0I / II25I / II20I / II15PET Self-Adhesive Polymer Modified Asphalt Waterproof MembraneJH-C200 This product is a kind of waterproof material that can be rolled, made of specially customized petroleum asphalt as the base material, supplemented by active additives and tackifying resin, with its upper surface covered with polyester film (PET film) and its lower surface covered with silicon coated isolation film.H-C200 can be widely used in a variety of waterproofing projects, especially for the following waterproofing projects:Product applicationsRoof and underground building waterproofingBase surface cleaning and repair → applying base treatment agent → node pasting → positioning tion Please noteIt should not be applied in rainy days or when the ambient temperature is below 5℃.When precipitation occurs during the application process, the area where the membrane has WATERPROOF PRODUCT MANUAL

06Packaging, transportation, and The storage temperature should be 5-45℃. The product should be stored to avoid the sun and When the membranes are stored flat, the stacking height should not be more than five layers, from the date of production.Executive standard of product performance: Requirements for inlay-free (class N) polyester film (PET) in GB 23441-2009 \"Self-adhering polymer modified bituminous waterproof sheet.\"performanceMain itemsTension N/50mm ≥Elongation at maximum tension % ≥N/mm ≥Persistent adhesivity min ≥Type I150No cracks at -20℃1.020Type IICharacteristicsElongation at break % ≥150Impermeable at 0.2 Mpa for 120 minNote: See the standard content for other requirements.WATERPROOF PRODUCT MANUAL

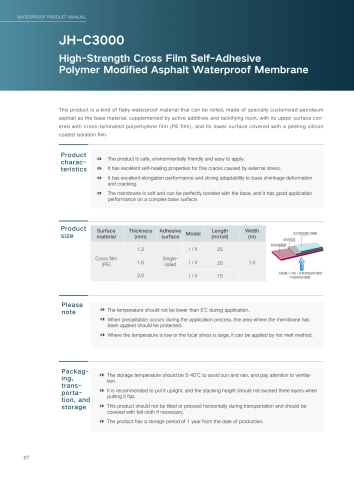

JH-C300007This product is a kind of flaky waterproof material that can be rolled, made of specially customized petroleum asphalt as the base material, supplemented by active additives and tackifying resin, with its upper surface covcoated isolation film.The product is safe, environmentally friendly and easy to apply.It has excellent self-healing properties for fine cracks caused by external stress.It has excellent elongation performance and strong adaptability to base shrinkage deformation The membrane is soft and can be perfectly bonded with the base, and it has good application performance on a complex base surface.The temperature should not be lower than 5℃ during application.When precipitation occurs during the application process, the area where the membrane has Where the temperature is low or the local stress is large, it can be applied by hot melt method.The storage temperature should be 5-45℃ to avoid sun and rain, tion.putting it flat.This product should not be tilted or pressed horizontally during transportation and should be covered with felt cloth if necessary.The product has a storage period of 1 year from the date of production.Packaging, transportation, and storagenoteSurfacematerialThickness(PE)Length(m/roll)1.21.5I / II2520AdhesivesurfaceHigh-Strength Cross Film Self-Adhesive Product characteristics

Base surface cleaning and repair → applying base treatment agent → node pasting → positioning and snapping lines → laying membranes → rolling and venting → sealing and lap → protective layer application08Executive standard of product performance: Requirements for inlay-free (class N) polyethylene film (PE) in GB 23441-2009 \"Self-adhering polymer modified bituminous waterproof sheet\".Main itemsTension N/50 mm ≥Low temperature flexibilityImpermeabilityPeel strengthN/mm ≥Persistent adhesivity min ≥Type I150Sliding does not exceed 2 mm at 70°CNo cracks at -20℃1.01.5Membrane andmembraneMembrane andaluminum sheetNo cracks at -30℃Elongation at break % ≥250200Type IICharacteristicsImpermeable at 0.2 Mpa for 120 minNote: See the standard content for other requirements.MethodmanceWATERPROOF PRODUCT MANUAL

JH-W100聚酯胎濕鋪防水卷材09performance.It has good puncture resistance and tear resistance.It can be fully bonded with the building structure to effectively prevent water from penetrating the gap between the waterproof membrane and the structure.The cement slurry or cement mortar is adhesive to the concrete base.It can be applied directly on the wet base surface, which is not significantly affected by the rainy weather, effectively shortening the application period.Cold application does not require the use of open flame, making it safe and fast, and no flue gas polluting the environment is generated, making it more energy efficient and environmentally friendly.is made of self-adhesive material made by our company using specially customized high-quality petroleum asphalt as the main material, supplemented by active additives and tackifying resin.InlayPYThickness(mm)Adhesive surfaceLength3.0Single-sided/double-sided101.0防水產(chǎn)品手冊JH-W100Polyester-Tire Moisture-LayingWaterproof MembraneProduct characProduct sizePlease storageately.ened when reinforcing bars or pouring concrete.Do not apply the membrane on the base surface with pollution, obvious water or ice.Cross-application is prohibited, and the application process should be completed step-by-step.The product should be stored in a dry and ventilated environment. The storage temperature The membranes of different categories and sizes should be stacked separately.pressed horizontally.The product has a storage period of 1 year under normal conditions.WATERPROOF PRODUCT MANUAL

It is suitable for roof and underground building waterproofing projects.Clean the base surface → wet the base surface (not required if the base is wet) → positioning and snapping lines → pre-laying → stirring and spreading cement slurry → laying membranes → lifting, g membranes → inspection and acceptanceExecutive standard of product performance: Requirements for the polyester tire (class PY) inGB/T 35467-2017 \"Wet installed waterproofing sheets.\"Note: See the standard content for other requirements.Main itemsElongation at maximum tension % ≥Heat resistanceLow temperature flexibilityImpermeabilityPeel strengthbetween membranes(overlap edge)/(N/mm)Persistent adhesivity /min ≥5003070℃No cracks at -20℃1.030Notreatment ≥Impermeable at 0.3Mpa for 120 min防水產(chǎn)品手冊Product application MethodProduct performanceWATERPROOF PRODUCT MANUAL

PET Polymer Reaction-Bonded MoistureLaying Waterproof MembraneJH-W20011This product is a waterproof material with a cost-effective advantage. It is made of self-adhesive material made by our company using specially customized high-quality petroleum asphalt as the main material, supplemented by active additives and tackifying resin. The material can be applied by moisture laying method or directly pasted by dry laying method.Surface materialPET polymermembraneAdhesive surfaceLength(m/roll)Width(m)1.52.0Single-sided/double-sidedSingle-sided/double-sidedProduct characteristicsProduct sizePlease noteThe membrane is soft, and the super-strong adhesive property is perfectly combined with the base, which is more suitable for the application of complex base surface.The cement mortar is adhesive to the concrete base, and the wet base surface can be applied.The creep resistance of the adhesive is excellent. It is easy to maintain and difficult to leak even if it is punctured.The application is easy. It can be applied by self-adhesion or moisture laying method.The cost performance is reasonable, and the application range is wide.Timely covering of the protective layer is necessary after application.Do not walk on the adhesive material before it has a certain strength.Heavy and sharp objects should not be placed on the waterproof layer after the completion of the membrane application.It is recommended to store the product in a dry and well-ventilated environment. The product should not be left out in the sun or the rain, and its storage temperature should not exceed 45°C.The membranes of different categories and sizes should be stacked separately, and laid flat.The membranes should be laid flat during transportation and should not be tilted sideways or pressed horizontally.The product has a storage period of 1 year under normal conditions from the date of production.Packaging, transportation, and storageWATERPROOF PRODUCT MANUAL

Moisture laying method: clean the base surface → wet the base surface → positioning and snapping lines → pre-laying → stirring and spreading cement slurry → laying membranes → lifting, venting, and airing → sealing overlap edge → cutting and sealing membranes → inspection and acceptance12Executive standard of product performance: Requirements for high strength class (class H) in GB/T 35467-2017 \"Wet installed waterproofing sheets\".Note: See the standard content for other requirements.Main itemsTension N/50 mm ≥Elongation at maximum tension % ≥Heat resistanceLow temperature flexibilityPeel strength betweenmembranes(overlap edge)/(N/mm)Persistent adhesivity /min ≥50Sliding ≤2 mm; no flowing and dripping70℃No cracks at -20℃1.030No treatment ≥CharacteristicsImpermeable at 0.3Mpa for 120 minApplication MethodProduct performanceWATERPROOF PRODUCT MANUAL

High-Strength Cross Film PolymerReaction-BondedMoisture-Laying Waterproof MembraneJH-W300013Surface materialCross filmThickness (mm)Adhesive surfaceLengthm/roll)Width(m)1.52.0Single-sided/double-sidedSingle-sided/double-sided20151.0JH-W3000waterproofmembraneConcrete baseSynergistic effect of chemical crosslinking andphysical meshing of reactive self-adhesiveInterfacelayerChemicalcrosslinkingInterfacial reaction sealCross-laminatedhigh-strength filmThis product is made by our company using high-strength cross film and reactive self-adhesive. The product is the perfect combination of fast reaction bonding technology and high-strength cross film with superiProduct characteristicsProduct Please noteExcellent physical properties: The high-strength cross film adopts cross-laminated technology, which has a comprehensive improvement in tensile strength, elongation, tear resistance, impact resistance, dimensional stability, weather resistance, and corrosion resistance compared with ordinary films.Superior adhesive properties: The chemical reaction and physical adsorption occur between the coil and the concrete structure layer through the cement slurry adhesive so that the coil and the structure layer form a permanent physical and chemical adhesive layer that is much stronger adhesive layer. It can solve the problems of tunnels and challenging applications in winter, has low requirements for the base, can shorten the application period while saving the application cost, and is easy to overlap.The base should be smooth, clean and free of water.Detail nodes are required for the pipes, internal and external corners, expansion joints, etc.slurry adhesive should be completely hardened before subsequent application.

It is suitable for non-exposed layers, basements, and indoor works of all kinds of buildings, as well as open-cut subways, tunnels, pools, and canals.Moisture laying method: clean the base surface → wet the base surface (not required if the base is wet) → positioning and snapping lines → pre-laying → stirring and spreading cement slurry → laying membranes → lifting, venting, and airing → sealing overlap edge → cutting and sealing membranes → inspection and acceptance14Executive standard of product performance: Requirements for high elongation class (class E) in GB/T35467-2017 \"Wet installed waterproofing sheets\".Note: See the standard content for other requirements.Main itemsTension N/50 mm ≥Heat resistanceLow temperature flexibilityImpermeabilityPeel strengthbetween membranes(overlap edge)/(N/mm)20018070℃No cracks at -20℃1.030Notreatment ≥CharacteristicsImpermeable at 0.3Mpa for 120 minProduct performanceThe product should be sealed in a special plastic bag and stored in a dry and ventilated environment. The storage temperature should not be higher thannot be exposed to the sun and rain.or pressed horizontally.tion, and WATERPROOF PRODUCT MANUAL

SBS Elastomer Modified AsphaltWaterproof MembraneJH-N10015The SBS elastomer-modified asphalt waterproof membrane is made of high-quality asphalt, styrene-butadiene-styrene (SBS), and elastomer resin, prepared by special technology into polymer-modified asphalt material with a reinforced matrix and covered with a variety of surface materials.InlayPYThickness(mm)Upper surfacematerialModelLength(m/roll)Width(m)3.04.0Polyethylene film (PE)/sand surface (S)/shale surface (M)Polyethylene film (PE)Sand surface (S)/shale surface (M)I / III / III / II10107.51.01.0Product applicationsWaterproofing of roofing projects for industrial and civil buildings.Waterproofing and moisture-proofing of underground projects for industrial and civil buildings.Waterproofing of indoor swimming pools, fire pools, etc.Waterproofing projects for highways, bridges and other municipal traffic.Product characteristicsProduct sizeIt has high tensile strength, good dimensional stability, and strong adaptability to base shrinkage deformation and cracking.It has good resistance to high and low temperature and it is especially suitable for cold areas.It has good puncture resistance, tear resistance, corrosion resistance, mildew resistance and weather resistance.It is convenient for application, can be operated by the hot melt method at all seasons, and its joint sealing is good.Please noteApplication is strictly prohibited on days that are rainy, snowy, or windy and are above the fifth grade.The temperature should not be lower than 0℃ during application.When precipitation occurs during the application process, the area where the membrane has been applied should be protected.Safety protection facilities should be complete at the application site, and fire fighting equipment should be placed in accordance with regulations.WATERPROOF PRODUCT MANUAL

16Executive standard of product performance: Requirements for the polyester tire (PY) inGB 18242-2008 \"Styrene butadiene styrene (SBS) modified bituminous sheet materials.\"Main itemsMaximum tension N/50 mm ≥Elongation at maximum tension % ≥Heat resistanceLow temperature flexibilityImpermeability50090℃ Sliding ≤2 mm; no flowing and drippingNo cracks at -20℃No cracks at -25℃30800105℃ 40CharacteristicsType IType IIImpermeable at 0.3Mpa for 30 minNote: See the standard content for other requirements.Packaging, transportation, and storageApplication MethodmanceDo not expose to sun and rain and pay attention to ventilation.The storage temperature should not be higher than 50℃. The product can only be put upright in a single layer or placed upright in no more than two layers during transportation.This product should not be tilted or pressed horizontally during transportation and should be covered with felt cloth if necessary.The product has a storage period of 1 year under normal transportation and storage conditions Hot melt method: base inspection and cleaning → applying base treatment agent → trial laying, positioning, and snapping lines → adding layer → large surface membrane application → rolling and venting → coating on the back of membrane → base coating → pasting, rolling and venting → edge sealing → fixing and sealing → cleaning, inspection, and acceptanceWATERPROOF PRODUCT MANUAL

APP Plastic Modified AsphaltWaterproof MembraneJH-N20017The product is made of high-quality asphalt and atactic polypropylene (APP) or polyolefin polymer (APAO, APO) modified resin, prepared by special technology into polymer-modified asphalt material, with a reinforced matrix and covered with a variety of surface materials structured together.Product applicationsIt has high tensile strength, high elongation, good dimensional stability, and strong adaptability to base shrinkage deformation and cracking.It has good resistance to high and low temperatures, especially suitable for building waterproofing in high-temperature environments.It has good puncture resistance, tear resistance, corrosion resistance, mildew resistance, and weather resistance.It is convenient for application and can be operated by the hot melt method at all seasons with reliable joints.InlayPYThickness(mm)Upper surfacematerialModelLength(m/roll)Width(m)3.04.0Polyethylene film (PE)/sand surface (S)/shale surface (M)Polyethylene film (PE)Sand surface (S)/shale surface (M)I / III / III / II10107.51.01.0Product sizePlease noteApplication is strictly prohibited on days that are rainy, snowy, or windy and are above the fifth grade.The temperature should not be lower than 0℃ during application.When precipitation occurs during the application process, the area where the membrane has should be placed in accordance with regulations.WATERPROOF PRODUCT MANUAL

18Packaging, transportation, and storageThe product should be stored to avoid the sun and rain, and pay attention to ventilation. The storage temperature should not be higher than 5-45℃. It iin a single layer.This product should not be tilted or pressed horizontally during transportation and should be covered with felt cloth if necessary.The product has a storage period of 1 year under normal transportation and storage conditions from the date of production.Application MethodHot melt method: base inspection and cleaning → applying base treatment agent → trial laying, positioning, and snapping lines → adding layer → large surface membrane application → rolling and venting → coating on the back of membrane → base coating → pasting, rolling and venting → edge sealing → fixing and sealing → cleaning, inspection, and acceptanceExecutive standard of product performance: Requirements for the polyester tire (PY) inGB 18243-2008 \"Atactic polypropylene (APP) modified bituminous sheet materials.\"Main itemsMaximum tension N/50 mm ≥Elongation at maximum tension % ≥Heat resistanceLow temperature flexibilityImpermeability500110℃ Sliding ≤2 mm; no flowing and drippingNo cracks at -7℃No cracks at -15℃2540CharacteristicsType IType IIProduct perforWATERPROOF PRODUCT MANUAL

Non-Asphalt-Based Polymer Self-AdhesiveFilm Waterproof MembraneJH-P20019It forms a permanent organic adhesion with the concrete, preventing moisture from seeping into the gap between the waterproof coil and the structure.No protective layer is required, and people can walk on the waterproof membrane immediately after application.It is bonded on one side, integrated with structural concrete, and is not affected by the displacement of the base layer.The application period is short, one third shorter than that of ordinary membranes.It is convenient for application, and the cast skeleton steel bar can be added after simple treatment.It can maintain high peel strength in long-term immersion.It has long service life and good weather resistance.It has excellent puncture resistance.The non-asphalt-based polymer self-adhesive film waterproof membrane is a multi-layer composite waterproof material with superior performance, including a high-density polyethylene (HDPE) polymer film, a high polymer adhesive layer, and reactive inorganic polymer particles in a unique process. It can be chemically cross-linked with the cast concrete and physical mortise and tenon to achieve high by the displacement of the base. It can maintain high peel strength in long-term immersion. This product is convenient for application, and the cast skeleton steel bar can be added after simple treatment.Product characteristicsProduct Please noteLower surfacematerialCovered with reactive sand/covered with solating membraneThickness(mm)Length(m/roll)Width(m)1.21.5/1.71.2/1.5/1.72520201.02.0When the membrane covered with sand surface is transversally bonded, the butting method is adopted. Double-sided self-adhesive strips are used to bond the membrane, and the width of the double-sided self-adhesive strips should not be less than 150 mm.For underground construction projects with complex structures, this material may cause a higher wastage.WATERPROOF PRODUCT MANUAL

20Packaging, portation, and storagePrevent sun, rain, and moisture; It should be stored in a dry and ventilated environment.The storage temperature should be 5 ~ 45℃.The membranes of different categories and sizes should be stacked separately and laid flat; The layer height should not exceed 5 layers.The membranes should be laid flat during transportation and should not be tilted or pressed horizontally.The product's storage period is 1 year under normal conditions from the date of production.Product applicationsThe non-asphalt-based polymer self-adhesive film waterproof membrane is specially designed for underground waterproofing difficulties, so it is only suitable for underground or tunnel waterproofing projects. It is not recommended for building ground walls or roof waterproofing.Application MethodCleaning base surface → snapping lines and positioning → trial laying of waterproof membrane → laying of waterproof membrane → membrane lap and detail node treatment → inspection → assembling reinforcement → pouring concreteExecutive standard of product performance: Requirements for plastic waterproofing sheets (class P)in GB/T 23457-2017 \"Pre-applied waterproofing sheets\".Main itemsTension N/50 mm ≥Tensile strength, Mpa ≥Elongation at break/% ≥Heat resistanceImpermeabilityPeel strength between membranes(overlap edge)/(N/mm)80℃ (2h)No sliding, flowing, and drippingNo cracks at -25℃60040016CharacteristicsImpermeable at 0.3Mpa for 120 minNo treatment ≥0.8Note: See the standard content for other requirements.Product performanceWATERPROOF PRODUCT MANUAL

Thermoplastic Polyolefin (TPO) WaterproofMembraneJH-P50021Thermoplastic Polyolefin (TPO) Waterproof Membrane is a new type of waterproof membrane made of thermoplastic polyolefin (TPO) synthetic resin combined with ethylene propylene rubber and polypropylene by using advanced polymerization technology, supplemented by antioxidant, anti-aging agent, and softener. It can be made of polyester fiber network cloth as internal reinforcement material to create an enhanced waterproof membrane, which is a waterproof product of synthetic polymer waterproof membrane. The product has no chlorine, heavy metals, or harmful ingredients to plant roots, making it environmentally friendly.It has excellent weather resistance, aging resistance, high tensile strength and high elongation.It has the features of wet roof application, protective layer not required for exposure, convenient application, no pollution, etc.Repeatable weldability.The white TPO membrane has a high sunlight reflectivity.It has the ability to resist the growth of mold and algae.Product characteristicsProduct sizeModelH(homogeneoussheet)L(covered withnon-wovenfabric)P(internal reinforcement)Thickness(mm)Length(m/roll)Width(m)1.21.5/1.82.01.2/1.525201520151.02.01.8/2.0Please noteThe surface of the welding material should be cleaned, and the surface should not be covered with water beads, oil, and dirt.A Pre-welding test should be done before formal welding to determine the temperature and speed of welding.Scope of applicationThe product is suitable for exposed buildings or non-exposed roof waterproofing, as well as easily deformed buildings' underground waterproofing. The product is especially suitable for light steel structure roofing.WATERPROOF PRODUCT MANUAL

22Packaging, transportation, and storageFor storage and transportation, products of different types and sizes should be stacked separately to avoid sun and rain and pay attention to ventilation. The storage temperature should not be higher than 45°C, the layer height of the square storage pile should not exceed 5 layers, and it is prohibited to contact with acids, alkalis, oils, and organic solvents.This product should not be tilted or pressed horizontally during transportation and should be covered with felt cloth if necessary.The product's storage period is 1 year under normal conditions from the date of production.Application MethodBorder adhibiting method:Base leveling and cleaning → snapping lines → Membrane pre-laying → Membrane joint overlap welding → special parts treatment → fixing and pressing → edge sealing of sealing material → acceptanceMechanical fixing method:Base surface cleaning → embedment of fixed parts → waterproof membrane laying and mechanical fixing → roof joint treatment → cleaning after completion → finished product protection → completion acceptanceCold adhibiting method:Base inspection, cleaning, and repairing → trial laying, positioning, and snapping lines → coating on the back of membrane → base coating → pasting, rolling, and venting → edge sealing of joint sealing material → fixing and sealing → cleaning, inspection, and acceptanceProduct sizeMain itemsMaximum tension N/cm ≥Tensile strength Mpa ≥Elongation at maximum tension % ≥Elongation at break % ≥Low temperature bendingImpermeabilityH(homogeneoussheet)L (covered withnon-woven fabric)CharacteristicsP (internalreinforcement)-200No cracks at -40℃Impermeable at 0.3Mpa for 120 min25012.0----15500250-Executive standard of product performance: Requirements for plastic waterproofing sheets (class P)in GB/T 23457-2017 \"Pre-applied waterproofing sheets\".Note: See the standard content for other requirements.WATERPROOF PRODUCT MANUAL

WATERPROOF

25Single-Component Polyurethane Waterproof CoatingJH-A100The single-component polyurethane waterproof coating is a kind of reactive wet-cured polymer waterproof coating. It is made from isocyanate and polyether polyol as the main raw materials, supplemented by a variety tough, soft, and jointless polymer waterproof film on the surface of the base layer by reacting chemically with Single-component; can be used straight from the box, easy to apply.The film has high tensile strength, good elongation, and excellent resistance to high temperatures and low temperatures.Product characteristicsProduct applicaIt is suitable for waterproof projects such as kitchens, balconies, roofs, basements, pools, and Reference amountt 1.5 kg/㎡-1.7kg/㎡ (Note: the actual Product packaging size: 25kg/barrel.It is placed upside down in a clean, dry, and airtight iron bucket.collision, and pay attention to ventilation, and the storage tPackaging, portation, and Product sizeComponentSingle componentModel

26GB/T 19250-2013 \"Polyurethane waterproofing coating\".Main itemsElongation at break ≥ImpermeabilityNote: See the standard content for other requirements.Performance torsPlease noteIt should be stored upside down, and it is recommended to use it up after unpacking. The application base surface should be dry and should not be rained after application.When the storage period of the material is relatively long, a thin film will be formed on the a solvent that does not react with polyurethane for base treatment, requiring thin coating and closing the base surface pores.hard and sharp objects to prevent damage to the waterproof layer.If it is used for the application of ordinary facades, sand should be scattered after the last dry.Applicapointsand the pipe fittings, sanitation facilities, and floor drains connected with the base must be firm and not allowed to lose. The anti-corrosion application of metal plates and pipes requires rust removal and treatment before coating application.structural joints: A rough surface groove with a width and depth of about 30-50 mm should be caulking material and brushed with a single-component polyurethane waterproof coating, fabric should be coated with a single-component polyurethane waterproof coating.coating and closing the base surface pores. After the first coating film is cured, the second increase the adhesion between the waterproof coating and the protective layer, the surface can be sparsely sprinkled with clean sand to enhance its roughness when the last coating film is not dry.WATERPROOF PRODUCT MANUAL

27Two-Component Polyurethane Waterproof CoatingJH-A200The single-component polyurethane waterproof coating is a kind of reactive wet-cured polymer waterproof coating. It is made from isocyanate and polyether polyol as the main raw materials, supplemented by a variety of additives and fillers through polymerization reactions. The polyurethane prepolymer's -NCO group forms a tough, soft, and jointless polymer waterproof film on the surface of the base layer by reacting chemically with the moisture in the air when it is coated on the waterproof base.The film is compact and elastic.It has strong adhesion and good adhesion with concrete, wood, metal, ceramics, etc.Components A and B can be fully mixed in proportion, making it easy to operate.Product characProduct sizeComponentTwo componentsCategoryComponentType IReference t 1.5 kg/㎡-1.7kg/㎡ (Note: the actual The application base surface should be dry, the application temperature should be 5-35℃, and mixing. If there are small pores on the base surface, it is necessary to dilute the two-component The product should be sealed and stored upside down in a dry, cool, and ventilated place.PackagstorageWATERPROOF PRODUCT MANUAL

28PackagtransportastorageThe product should be stored in a clean and sealed iron bucket and stored upside down in a ventilated, dry, and cool place to prevent direct sunlight. In addition, the storage temperature rain in order to ensure the packaging remains intact.Product applicationsUnderground works, toilet, bathroom, kitchen, balcony, pool, parking lot, and other waterproof works.Application pointsstructural joints: A rough surface groove with a width and depth of about 30-50mm should be layer of mesh non-woven fabric for enhancement. Then, the fabric should be coated with polyurethane twice.minutes, the mixed material should be used up within 20 minutes. If there are many small pores with the polyurethane for base surface treatment. The mixed coating should be applied evenly on the base surface during application. The thickness of the coating film is generally 1.5-2.0 vertical, and the time interval is subject to the non-stick coating film by hand. In order to enhance the adhesion of the waterproof layer and the protective layer, before the last coating is cured, the coarse sand should be sprinkled on its surface to strengthen the adhesion between non-woven fabric can be applied after the first coating for enhancement, and then the If it is used for the application of ordinary facades, the sand should be scattered after the last dry.The executive standard of this product meets the single-component requirements of GB/T 19250-2013 \"Polyurethane waterproofing coating\".Main itemsElongation at break ≥Impermeable at 0.3Mpa for 120 minNo cracks at -35℃PerforindicaWATERPROOF PRODUCT MANUAL

29Non-cured Rubber Asphalt JH-G300The product is a new type of environmentally friendly hot-melt asphalt waterproof coating with high solid content. It has the characteristics of thick gum. At the same time, the viscosity of the creep material makes it able to seal the capillary pores and cracks of the base well and solve the water channeling problem of the waterproof layer.Excellent creep performance: It can effectively absorb stress from the base. When external stress acts, it can immediately produce deformation to protect the waterproof layer from damage, improve its reliability, and extend its service life. Excellent bonding performance: once Excellent temperature adaptability: It does not slip at 65℃ hif layer is damaged by external at the bottom of the waterproof layer, and since the creep of the coating can gradually repair Product teristicsWidely used in industrial and civil building roof and underground waterproof projects. Grouting projects of deformation joint.This product is applied together with the coil to form a reliable composite waterproofing system.Product applicationsDuring transportation and storage, different types of products should be stacked separately and should not be mixed. Do not approach the fire source, avoid the sun and rain, prevent collision, and t exceed 40℃.tions from the date of production.PackagtransstorageProduct sizeWATERPROOF PRODUCT MANUAL

30It can be used as a waterproof adhesive to paste a waterproof coil to form a structural composIt has an excellent bonding effect with all kinds of waterproof coils (including hot-melt waterproof coils, PVC waterproof coils, etc.) and can form a composite waterproof layer.channeling.waterproof layer due to the structural deformation. Especially when it is combined with the coil to form a composite waterproof layer, the JH-G300 non-curing rubber asphalt waterproof coating force to ensure that the entire composite waterproof layer remains intact for a long time.Application pointsMain technical performance of the product (according to JC/T2428-2017 standard).Note: See the standard content for other requirements.Main itemsElongation ≥Heat resistanceWet base surface98%No fractures at -20℃Performance indicaWATERPROOF PRODUCT MANUAL

31Polymer Cement Waterproof CoatingJH-J100The polymer cement waterproof coating is a two-component waterproof coating composed of or-ganic polymer emulsion and inorganic powder. It has both the flexibility and toughness of an organic material and the durability of an inorganic material. After coating, it can form a waterproof layer with good strength and high resilience for effective waterproofing.Strong and resilient coating with good elasticity that can adapt to base cracking and shrinkage deformation.Good adhesion, can be directly painted on the wet base surface with no obvious water.Non-toxic and odorless, suitable for waterproofing food-grade water tanks.Good heat and aging resistance; acid, alkali, and salt erosion resistance; long waterproof layer life.Product characPrimarily used for waterproofing, leakage prevention, and moisture resistance in bathrooms, kitchens, roofs, basements, tunnels, roads, bridges, and pools.Suitable for moisture-proofing and leakage prevention in porous materials such as aerated concrete and hollow bricks.Product applicationsThis product is an environmentally friendly coating and can be transported as general cargo. During transportation, the product should be protected from rain, direct sunlight, freezing, squeezing, and physical shock, in order to ensure the packaging remains intactThis product should be sealed and stored at 5℃-40℃.not be used until they pass re-inspection.Packaging, transportation, and storageProduct sizeComponentType ISizeType II25kg/barrelWATERPROOF PRODUCT MANUAL

32Base surface treatment: The base surface should be flat and firm, without hollows; any dust, oil stains, dirt, and other loose materials should be removed, and obvious pores and sand holes should be filled with cement mortar. The internal and external corners and tube roots should be repaired into a circular arc shape using sealing materials. If the air temperature is high or the base surface is dry, before applying the product, the base surface should be moistened with clean water, and no water should accumulate on the base surface.Application pointsThe ingredients should be prepared in strict proportion and stirred evenly. The stirring time should not be less than five minutes.The application temperature should be between 5℃-35℃. During application, maintain good air circulation in the application environment and do not carry out any work in environments with humidity greater than 85%, or this will affect the film-forming effectContinue stirring intermittently during application to prevent any precipitation within the slurry.After the work is completed, the area must not be stepped on for 24 hours, and the waterproof layer should be protected against damage.Application of protective coating can be carried out only after the coating is completely dry. Generally, the drying time is 3-5 days.The stirred slurry should be used up within 60 minutes, and the amount prepared each time should not be too much; the slurry should be used immediately once prepared.Application pointsThe physical and mechanical properties of the product should comply with the requirements of the JC/T 864-2008 standard.Main itemsSolid content ≥Tensile strength ≥Elongation at break ≥ImpermeabilityLow temperature flexibility70.0 %1.0 MPa1.5 MPa200 %80 %Impermeable at 0.3Mpa for 30minNo cracks at -10℃-CharacteristicsIIIPerformance indicatorsNote: See the standard content for other requirements.WATERPROOF PRODUCT MANUAL

33Acrylic Ester Waterproof CoatingJH-J300This product is prepared in scientific proportion based on acrylic polymer emulsion and fine fillers as the main raw materials, supplemented by imported high-performance waterproof additives and other auxiliary materials. The coating has excellent waterproof performance and good extensibility after volatilization of water to form a film. It is suitable for waterproof and moisture-proof buildings with slight vibration and deformation.Water-based coating, non-toxic, environmentally friendly, and pollution-free.It can be used for waterproof roofing, can be made in various colors, and can beautify the It has excellent low-temperature performance, extensibility, water resistance, and crack Easy application and short application period.Product characIt is used for moisture resistance. It is coated in one layer, with a thickness of about 0.5-0.7mm, It is used for water resistance. It must be coated in more than two layers, with a thickness of about 1.0-1.2mm, consuming about 2.2-2.4kg/㎡.The actual amount depends on the base condition and the thickness of the coating.Reference amountIt is required to be applied in an environment of 5-35°C, and application in a sun-exposed environment should be avoided in summer. Before the coating dries, pay attention to prevent rain, direct sunlight or cold. Tools and equipment should be cleaned with water immediately after One coating should not be too thick, which should generally be controlled at 0.5-0.7mm. Flexible materials cannot be used for the waterproof application of tile parts, and a protective layer is required after the waterproof layer is coated and dry.Otherwise, the closed water test may destroy the undried waterproof coating and produce coating damage.Please noteProduct size25kg/barrel, single-componentWATERPROOF PRODUCT MANUAL

34This product is a non-flammable and non-explosive environmentally friendly coating and can be transported as general cargo.The product should be protected from rain, direct sunlight, freezing, squeezing, and physical shock in order to ensure the packaging remains intact.Packaging, transtion, and storageProduct applicaThe product is suitable for water, seepage, and moisture resistance of roofing, walls, toilet bathrooms, basements, and pools in various old and new buildings and structures.Application processThe physical and mechanical properties of the product should comply with the requirements of the JC/T 864-2023 standard.Main itemsElongation at break ≥Impermeability65.0 %300 %No cracks at -15℃PerforNote: See the standard content for other requirements.WATERPROOF PRODUCT MANUAL

35Acrylic High-Elastic Waterproof Coating for RoofingJH-J800The primary material of this product is a premium acrylic emulsion, which is then enhanced by carefully chosen pigments, fillers, and a range of functional additives through scientific proportion proprovide lasting protection against a variety of base materials.Can be used straight from the box, easy to apply.Good low temperature bending performance.Excellent thermal insulation, reflection, and UV resistance to extend the service life of the base Product characteristicsDirectly exposed metal roofing waterproof projects such as color steel roofing.It is suitable for use with other roofing systems, such as concrete.Scope of applicaThe product should be ventilated and dry when stored to prevent direct sunlight, and the storage temperature should be between 5℃ and 40℃.From the date of production, the storage period of the product is 6 months under normal re-inspection.PackagProduct sizeWATERPROOF PRODUCT MANUAL

36Base treatment: The base should be flat, with no floating ash, oil, rust, or water; the loose firmware should be strengthened, and the rust parts should be ground. When it is used for color steel roofing with corrosion or serious damage or concrete roofing, base coating is required for external corners, expansion joints, drainage pipes, and joints, should be strengthened, and the enhanced polyester cloth should be embedded in the coating for reinforcement treatment so and warping.be divided into 2-3 times. After the first coating is dry, the second coating should be carried out. The coating time interval should be generally 12h, the drying time in low temperature or high humidity environment should be appropriately extended, and the thickness of each coating film should be perpendicular to each other, and the coating should be uniform without missing coating.Quality requirements for the coating surface: The color should be consistent without sand holes, allowed.ApplicapointsThe application temperature should be 5℃ ~35℃, the relative humidity should be below 85%, grade 5.There may be slight delamination before the coating is used after unpacking. The product should should be sealed and stored to prevent the coating from being contaminated and dry.clean water in time, and the tools should be cleaned with tap water immediately after application.Before the coating is dried, it is forbidden to walk on the waterproof layer. It is also necessary to ApplicaThe product's main technical performance should comply with the standard requirements of JG/T 375-2012 \"Acrylic waterproof coating for the metal roof\"Main itemsTensile strength/Mpa ≥Elongation at break/% ≥Low temperature bendingHeat resistanceImpermeabilitySolid content/% ≥1.5150No cracks at -30℃No crack, blistering or peeling at 90℃Impermeable at 0.3Mpa for 30 min65Note: See the standard content for other requirements.PerforindicatorsWATERPROOF PRODUCT MANUAL

37Cementitious Capillary Crystalline Waterproof CoatingJH-J200The cementitious capillary crystalline waterproof coating is an environmentally friendly new rigid waterproof green material produced by the introduction of advanced technologies. It is a gray powdered, inorganic material made of imported additives, special cement, specially selected quartz sand, and a variety of polymer active masterbatches. When the material reacts with water, the active substance can penetrate into the concrete, forming water-insoluble crystals and blocking crete, and the overall waterproof and impermeable ability of concrete is improved.It has good penetration properties. Both the upstream and downstream faces of concrete can achieve impermeability and waterproof effect.It is an inorganic mixed rigid material with excellent aging resistance, mildew resistance, acid It can be used for the application of a wet base with no obvious water, and the application is convenient and fast.It has the ability to repair fine cracks automatically and forms mesh crystals when it encounters water, thus blocking concrete pores and tiny cracks.It can protect concrete from acid rain and seawater erosion, thus effectively reducing the Product characteristicsDuring the application, the base surface should be treated, and the concrete base surface should be solid, flat, clean, and fully wetted to facilitate penetration. When mixing, the ratio of time and must be used up within 20 minutes. During use, the water and material cannot be It cannot be applied in rainy days or when the ambient temperature is below 5℃. Exposure to protected from rain within 24 hours after application and prosewage, and low temperatures below 5℃ within 48 hours.When brushing, a semi-hard nylon brush should be used, and horizontal brushing should be thickness, and no missing coating is allowed. There should be no thick deposits in the internal corners and depressions, otherwise it may crack. Generally, it is brushed two times, and it is not appropriate to brush too much at a time to avoid too thick coating and difficult maintenance. It should also not be brushed too thin, so as not to lose water too quickly and produce powder.Please noteProduct sizeComponentClass CSize25kg/barrelWATERPROOF PRODUCT MANUAL

38This product is an environmentally friendly coating and can be transported as general cargo. During transportation, the product should be protected from rain, direct sunlight, freezing, The product should be stored in a cool, dry, ventilated place. The storage temperature of the tation and storage conditions is 1 year from the production date. Expired products must not be Packagtransportation, and It is used for waterproofing application of subways (station, tunnel), slurry walls, highway and railway tunnels, cable tunnels, underground culverts, underground concrete or steel-concrete pipelines, industrial and residential building basements, underground parking garages, civil It provides plugging application for structural cracks (micro-cracks), water seepage points, and It provides anti-corrosion measures for concrete structures and cement mortar.tionsBase surface treatment: Remove floating slurry, dust, oil, and other debris on the surface of the base, and then rinse it with water so that the water can fully penetrate into the base surface, and it should be wet with no obvious water.(0.3-0.45) (weight ratio). It can be adjusted as needed based on actual conditions. A nylon hours. If the surface is too dry, moisten it with water before application. The mixed adhesive stir frequently. Ensure that the application is even without white spots or deposits in uneven areas. After the coating is in the semi-dry state, it shall be cared for with a misty sprayer 2-3 times per day for 2-3 consecutive days to prevent premature drying.pointsThe executive standard of this product meets the single-component requirements of GB 18445-2012 \"Polyurethane waterproofing coating\".Main itemsFineness, 0.63 mm residue on sieveApplicationpropertyAfter adding water and stirring20 min≤5 %2.8 MPa15.0 MPa1.0 MPaFree coatingFree coatingCharacteristicsNote: See the standard content for other requirements.PerforWATERPROOF PRODUCT MANUAL

Polymer Cement Waterproof MortarJH-J500The polymer cement waterproof mortar is a dry powder product prepared using high-quality cement, refined quartz sand, filler, modified emulsion powder, and other additives. It provides good waterproofing and impermeability features. In addition, it is non-toxic, harmless, green, and environmenThis product consists of hydraulic material, making it environmentally friendly.Excellent impermeability.Product characteristicsAfter the work is completed, the area must not be stepped on for 24 hours, and the waterproof layer should be protected against damage.The application temperature should be between 5℃ and 35℃.erature.The stirred slurry should be used up within 45 minutes, and the amount prepared each time should not be too much. The slurry should be used immediately once prepared.Please noteProduct sizeComponentSingle componentSizeModelScope of applicationks; Underground (such as pile Referdepends on the actual situation of the base surface and the required thickness of the waterproof 39WATERPROOF PRODUCT MANUAL

This product is a non-flammable and non-explosive material and can be transported as general cargo. During transportation, the product should be protected from rain, direct sunlight, freezing, squeezing, and physical shock to ensure the packaging remains intact.freezing, and extrusion collision.Packaging, portation, and Base treatment: The floating dust, oil, and other debris in the base should be cleaned up, the protrusion and loose parts should be removed, and the defective parts should be filled with mortar. At the same time, the base should be thoroughly wet with clean water, but there should Preparation of mortar: The amount of water added can be seen in the packaging certificate. The Application of mortar: The application thickness should be usu2. After the first polymer waterproof mortar is hardened, the second coating should be carried out, and so on.3. After the last application is completed, maintenance should be carried out after it is hardened. The maintenance time should not be less than 7 days.Application pointsMain technical performance of the product (according to the JC/T 984-2011 standard).Note: See the standard content for other requirements.Setting timepressureFlexibility ≥Dry base surfaceMortar specimen ≥24 h0.8 MPa7dCharacteristicsIPerformance 40WATERPROOF PRODUCT MANUAL

igveg dae:2024/07*Reprinting or printing of the product information in this material is forbidden without the consent of the Company.onal Petroleumong) WaterprooPreium roducturCveNaturalr, lCNPW

該頁無縮略圖

該頁無縮略圖